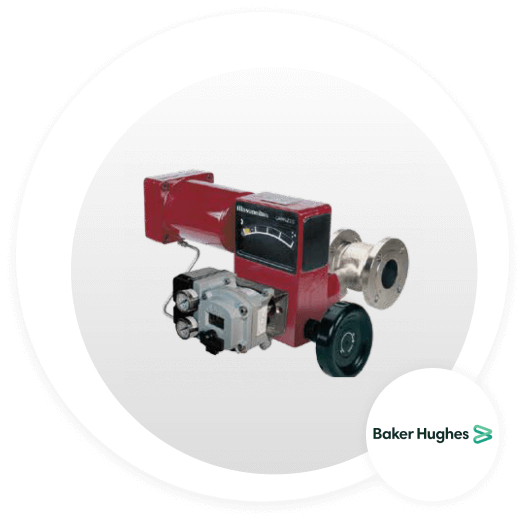

The Camflex II eccentric plug control valve effectively combines enhanced control performance, simplicity and long-term reliability for a broad range of applications.

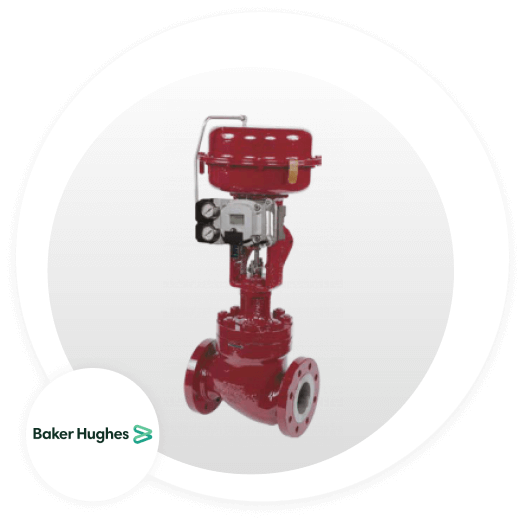

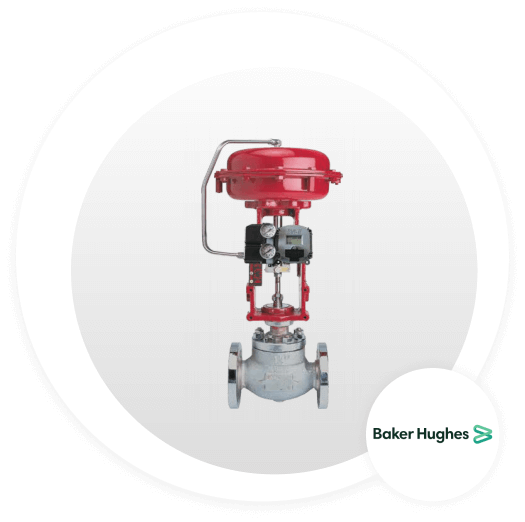

Dependable globe-style control valve solutions for maximum performance in severe service conditions

The Baker Hughes Masoneilan 21000 Series heavy top-guided globe valve for a wide range of automated process control applications. The 21000 Series product line features a single-ported design configuration, which permits numerous trim, actuation, and instrumentation solutions

The 80000 Series is a three-way control valve designed for either combining or diverting applications. It is well-suited for applications requiring high capacities with low-pressure recovery.

The Masoneilan LincolnLog is the premier high-pressure liquid-letdown valve in the process control industry.

It is a field-proven severe-service solution for cavitating and erosive applications in various industries. The LincolnLog is uniquely designed to operate reliably in harsh environments and dirty liquids.

Axial Flow LincolnLog design utilizes a tortuous path to distribute pressure drop along the axis of the plug. The axial stages throttle in unison as the plug strokes, maintaining staging ratios at all lift points. Velocity and pressure drop are controlled, thus eliminating cavitation and the resulting trim damage. This valve is highly effective in pump recirculation and high-pressure liquid letdown applications, including those found in Hydrotreater processes.

The SVI II AP is an Advanced Performance positioner with HART® protocol, local display, and pushbuttons for single and double-acting pneumatic control valves. Its universal and modular design with proven non-contact position sensor fits many applications offering high-performance valve control with real-time diagnostics.

Designed for special applications such as hydrocarbon service involving severe operating conditions where high temperatures and/or high pressures, high-pressure drops, severe coking conditions, erosive fluid particles, and flashing liquids are encountered. They are particularly adapted to pressure or level control systems and emergency blowdown or dropout service.

The base level 74000 series valve is characterized by a single stage trim, packaged in an angle style valve body, and having relatively simple flow geometry, for both the valve body and trim. This simplicity of flow path has proven successful in targeted heavy oil applications where high-velocity erosive jets are destroying more complex valve trims. This product has been uniquely successful in tough refining applications where entrained solids are the primary concern, and where other conventional severe service trims have failed catastrophically. The 74000 has industry-wide endorsements for success under the toughest of conditions and is frequently specified by name with experienced users. When seeking products that are differentiated in the market, the 74000 stands out as unique in both design and performance.

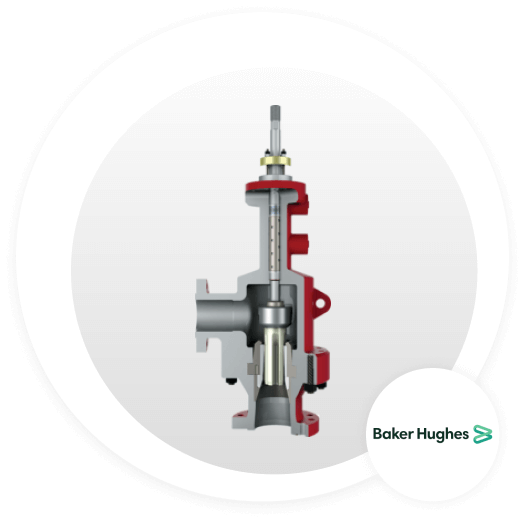

The patented innovation of the Dual Media trim design makes it the first and only spring-loaded safety relief valve in the industry that is “dual certified”, as defined by API Standard 520 Part 1 – Sizing and Selection, 10th Edition. Dual Certified is defined as pressure relief valves that are both vapor/gas flow certified and liquid flow certified where dual certification is achieved without making any modifications or adjustments to the relief device when switching fluids during the flow testing. The 1900 DM trim is engineered to perform on both liquid and/or gas media with exceptional blowdown performance and is dual certified to meet dual media (liquid and gas) capacity stamping per ASME B & PVC Code Case 2787. The 1900 DM trim is ideal for any liquid or gas application, two-phase liquid and gas, flashing or multiple relief case scenarios.

A full-nozzle pilot valve matching API 526 Direct-Spring PRV dimensions enabling modernization and carbon footprint reduction.

The new 2900 features several design innovations to solve customers’ biggest challenges

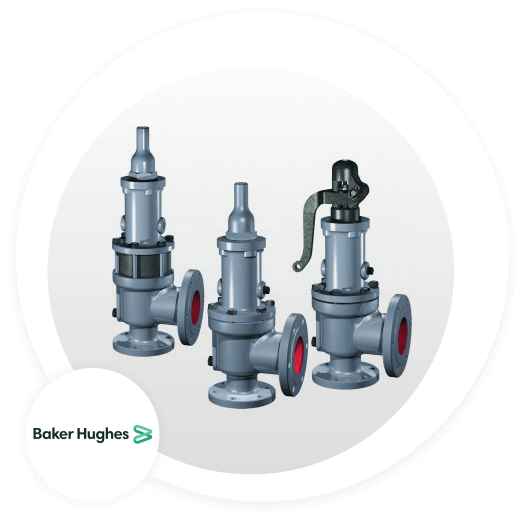

The highly adaptable Consolidated 1900 series safety relief valve is designed to meet numerous application requirements.

Offering proven, high-performance design for low-pressure, steam heating boilers and steam generators, as well as air service applications.

Consolidated 2900-40 Series Safety Relief Valve from Allied Valve

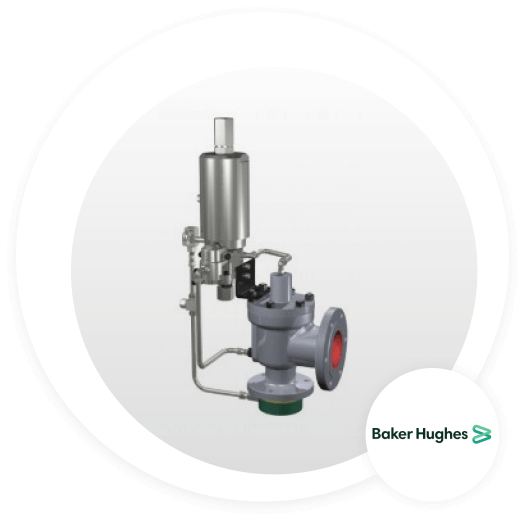

The Consolidated 2900-40 Series Pilot-Operated Safety Relief Valve is designed for demanding ASME Section I economizer and boiler applications.

Accurate, Responsive and Reliable

The third generation Baker Hughes Masoneilan™ SVI™ is a user friendly digital valve positioner for pneumatic control valves. Utilizing advanced control and diagnostic algorithms, along with field-proven noncontact position sensing technology, the SVI delivers accurate, responsive, and reliable positioning performance.

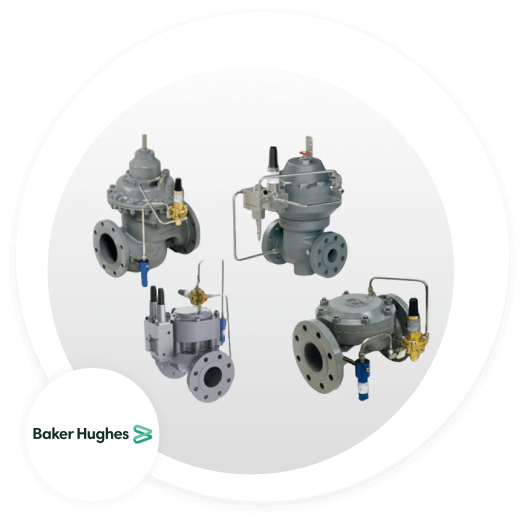

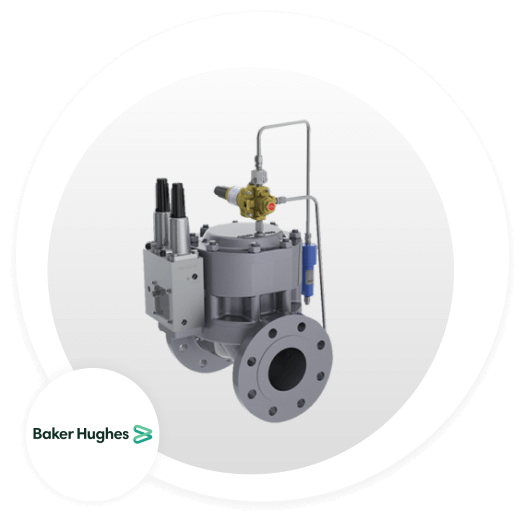

Baker Hughes’s Mooney regulators allow users to maintain pressure and flow control of almost any gas or liquid.

The ability to control pressure and flow increases accuracy of use, responsiveness and stability while decreasing parts, noise levels and maintenance and energy costs.

Mooney regulators add value for customers looking to produce energy more efficiently and reliably with less expense and greater awareness of environmental responsibility.

As self-contained, pilot-operated devices, these advanced technology solutions can offer substantial energy savings when compared to conventional air-operated or electrically operated control valves.

Helping the Natural Gas Industry Increase Efficiency and Performance.

Baker Hughes’ Mooney Flowgrid Regulator is an easy-to-maintain valve for self-contained pilot systems that allows users to maintain pressure and flow control of almost any gas or liquid

As a self-contained, pilot-operated device, the advanced technology solution can offer substantial energy savings when compared to conventional air-operated or electrically operated control valves.

Baker Hughes has drawn upon our leading product technology and application expertise to develop the Mooney Flowgrid Slam Shut regulator.

The Slam Shut regulator provides accurate, reliable secondary downstream pressure protection by shutting off the flow of gas when the sense or outlet pressure in the system either exceeds or drops below the set pressure point.

The device can stand alone or be integrated with a Mooney Flowgrid regulator.

Baker Hughes has an unflagging commitment to quality and safety, we have secured global PED EN 14382 certification for the Slam Shut regulator for sizes 2-4 inch.

The certification was awarded by DVGW (the German Technical and Scientific Association for Gas and Water), one of the world’s most recognized industry certification bodies and the largest gas and water industry certification agency in Europe

Mascot Dynamics is a trusted control valve dealer in India, providing precise flow, pressure, and customizable actuation for critical industrial processes. Throughout India, we are preferred control valve distributors for oil & gas and petrochemicals